The centering degree of die plate and pelletizing knives matching.

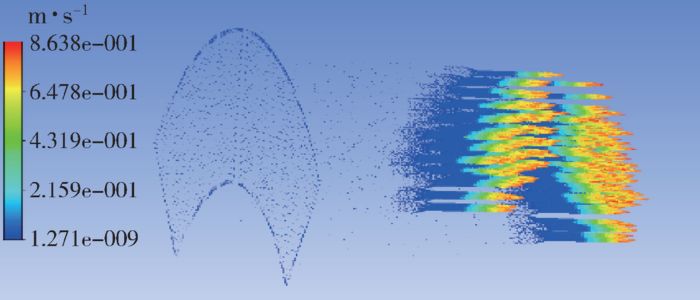

Underwater pelletizing process, high-speed rotation of the pelletizing knives affixed to the die plate, through high-speed rotation, the polymer out of the die hole to cut off. Installation process, the requirement of die plate and pelletizing knives matching the degree of centering to meet the technical requirements, to avoid the two collision damage and wear.

Clearance between die plate and pelletizing knives.

Gap affects the granulation molding, gap is too large, easy to form trailing particles, gap is too small, and granulation template friction wear. When adjusting the gap, need to consider the gap caused by the thermal expansion coefficient and vibration of high-speed operation, the comprehensive consideration of the gap left 0.03-0.05mm. Trial cutting debugging: pay attention to observe the deformation of granular plastic, gradually loading gap. Check the surface scratches of the pelletizing template during the process.

Pelletizing knife blade hardness.

Pelletizing knives must have and die plate to match the hardness of the cutter, pelletizing knives material is too hard will make the template and pelletizing knives wear serious, shorten the service life. Pelletizing knives material hardness is too low, will cause excessive wear of the knife, resulting in product failure.

The sharpness of the pelletizing knives has a great impact on the appearance of the product, the sharper the knife, the smoother the cross section of the particles, and vice versa, the phenomenon of trailing or even sticking.

Surface roughness of the die plate.

The surface roughness of the die plate pelletizing belt should meet the requirements, otherwise it will cause the pad knife, particle debris, affecting the die plate and the best match of the pelletizing knives.

Effect of pelletizing water on pelletizing.

Pelletizing water circulation volume, pressure and temperature have a great impact on product quality. Circulation volume is too small, easy to string grain and other faults. If the water temperature is too high, accidents such as stringing grain, tangling knife and enema will occur. Too low water temperature will lead to low temperature of the moldboard, easy to freeze and block the die hole, at the same time, the resin becomes very brittle, and the debris increases when cutting grain.