Die Plate For PS

| Products: |

PS |

|---|---|

|

Number Of Holes: |

300~1200 |

|

Hole Diameter: |

0.5~1.2mm |

|

Diameter: |

300~600mm |

|

Production Output: |

800~ 3500 kg/h |

|

Scheer Pelletizer: |

UWP |

|

BKG Pelletizer : |

Optigon |

|

Coperion Pelletizer: |

UG |

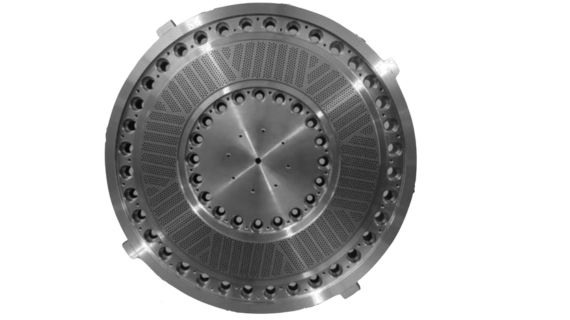

DOMIC Pelletizing Die Plate: Innovative Solution for PS Underwater Pelletizing

PS (polystyrene) is a high value-added engineering plastics, underwater pelletizing process, the pelletizing die plate has high requirements for structural accuracy, stability, corrosion resistance. DOMIC industry has more than 20 years of experience in the production of independent research and development of WC-CoNiCr metal-ceramic composite material technology for chemical customers to solve the problem of production. Provide excellent performance of the pelletizing die plate.

Digital Simulation, New Technology Validation

DOMIC pelletizing die plate using finite element analysis software Fluet, the fluid state of the pelletizing die plate simulation simulation; using structural analysis software ANSYS, the pelletizing die plate force distribution analysis, to ensure that the difference with the actual stress distribution <5%. Through the software analysis, the mathematical model of PS melt flow is established, and we optimize the number of die holes, density, and flow channel design of the die plate:

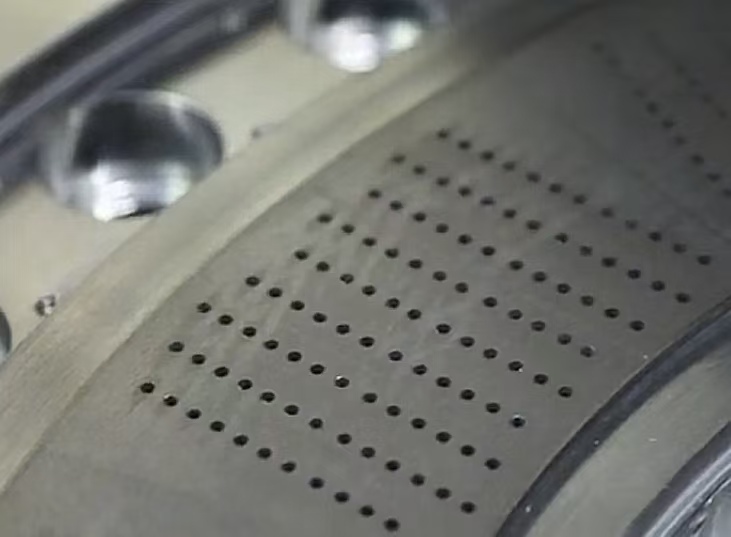

Ⅰ Outlet die holes use a stepped design with a length-to-diameter ratio (8:1~10:1), and give priority to using a small length-to-diameter ratio to reduce the shear force.

Ⅱ As PS is a high viscosity melt, to ensure the smoothness of the fluid, the discharge section uses a two-stage stepped design to control the cone angle.

Ⅲ The surface roughness of the die plate is controlled within Ra0.2 to ensure the best fluidity of PS melt.

Material Science, Solving Industry Pain Points

Molten PS is extruded into strips through the pelletizing die plate at a temperature of 220-250°C, and cut into pellets by the rapidly rotating cutter inside the pelletizing chamber, by the cooling circulating water, which cools and cures the pellets and circulates them away.

The conventional design of pelletizing die plate for PS underwater pelletizing system: die hole: 1.5mm~3.0mm, L/D ratio: 8:1~10:1.

PS underwater pelletizing unique high temperature and high pressure, DOMIC adopts WC-CoNiCr metal-ceramic composites:

Ⅰ low coefficient of thermal expansion: to ensure that the pelletizing template maintains the dimensional accuracy in the high temperature of 280 ℃ for a long time under the environment, to avoid the particles caused by the thermal changes. Low coefficient of thermal expansion

Ⅱ Strong corrosion resistance: Because of the application of Ni-Cr alloy, the corrosion resistance to chlorine ions is enhanced by more than 3 times.

Ⅲ Extreme hardness: hardness HRA92.5 exceeds traditional mold steel by more than 40%, and wear resistance is increased by 30%. Impact resistance is 2 times that of common alloys.

System Certification to Help Efficient Granulation

DOMIC has passed the ISO9001/ISO14001/ISO45001 tri-system certification, and has obtained obtained CE and ROHS certificates to meet EU requirements.

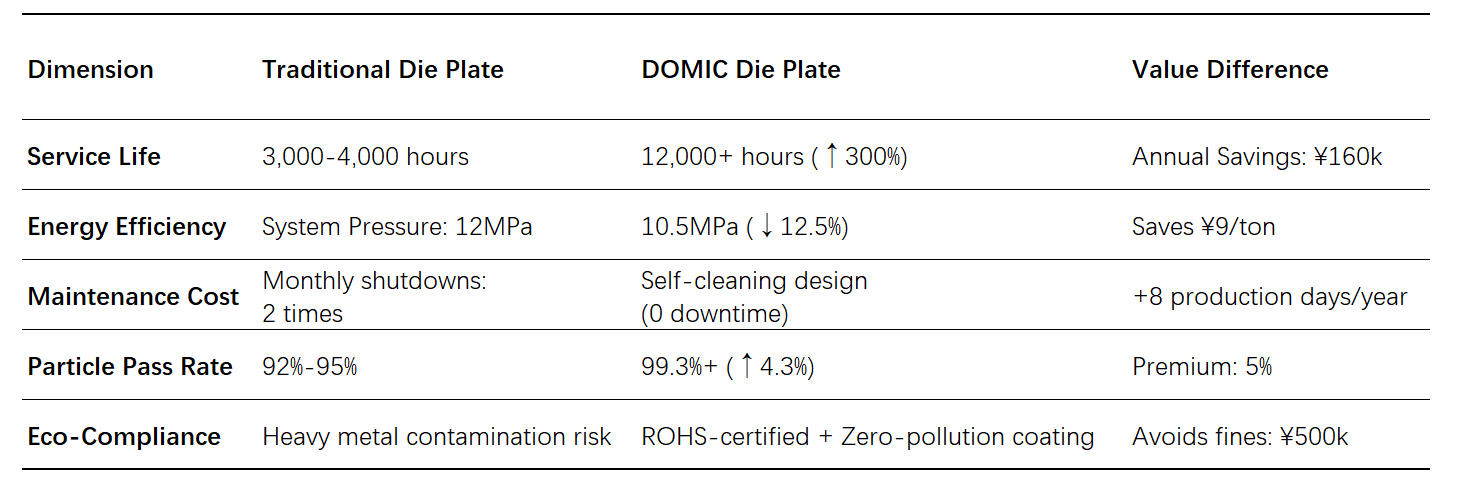

Digital simulation design, polishing process, make the product more excellent. Summary statistics, as shown in the figure.

At present, DOMIC pelletizing die plate have been successfully applied to chemical customers in 9 countries/regions around the world, helping customers to improve their results:

Capacity increase of 15%-22%

Reduction of energy consumption by 8.6% per ton

Reduction of annual maintenance cost by 40%

Please contact DOMIC to customize your own solution, and let the professional die plates improve the competitiveness of production for you!