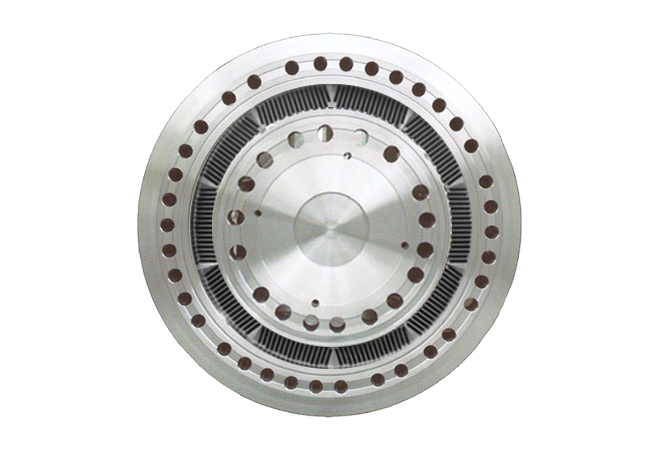

Die Plate For PP

| Products: | PP |

|---|---|

|

Number Of Holes: |

1496~3104 |

|

Hole Diameter: |

2.5~2.6mm |

|

Diameter: |

790~1300mm |

|

Production Output: |

200,000~ 400,000 tons per year |

|

CWP Pelletizer: |

ZSK350 ZSK320 |

|

JSW Pelletizer: |

CMP387 CMP335 CMP308 |

|

KOBE Pelletizer: |

LCM450G |

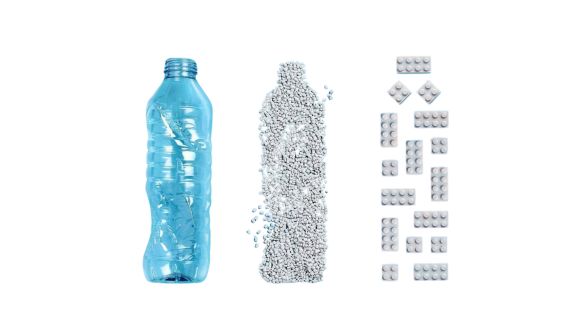

DOMIC- Helping to Produce PP Pellets Efficiently

The pelletizing die plate is the core accessory of the underwater pelletizer. Molten polypropylene (PP) passes through the pelletizing die plate, is cut off by the cutter and then enters the cooling circulating water for molding, so the pelletizing die plate has a very big influence on the appearance and quality of the pellets.

DOMIC has over 20 years of design and manufacturing experience and is ISO 9001 certified. We simulate the use of the die plate through simulation design, and optimize the cutting effect in the pre-design to provide the best products for our customers.

Face Challenges

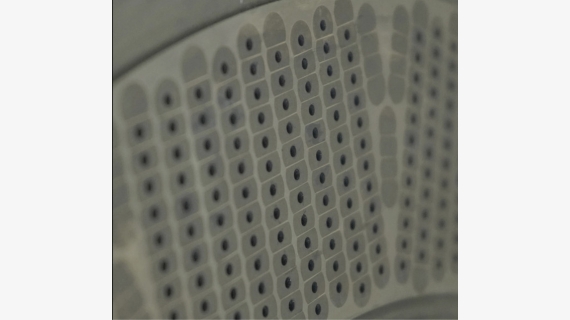

Fatigue-resistant: no micro-cracks on the granulation belt in the alternating hot and cold environments of heating and cooling circulating water.

High wear resistance: production of composite PP and filled PP (with talc and glass fibers, etc.); high speed cutting and chipping affects the wear of the granulation belt.

Poor flowability: the design of mold hole diameter, taper and step need to be matched with the opening area. Design parameters need to be repeatedly verified to avoid too low flow rate, which causes fluid pressure fluctuation and partial solidification.

Software Simulation

The basic parameters of the pelletizing die plate for the production of PP pellets: pore diameter 2.5~3.8mm, heating temperature: 230-280°C, surface hardness HRC75 or more, open area 40-50%.Ensure trial use in a variety of composite materials PP, pelletizing size, melt fluidity and expected yield.

However, in order to reduce fluid resistance, stable yield and melt pressure, further optimized by finite element analysis technology Fluent, die hole cone angle, open area, hole arrangement and other factors.

Case: production of thin-walled injection molded particles PP pelletizing die plate, software simulation: die hole diameter 2.2 mm, opening rate of 45%, cone angle of 55 °, to increase the melt fluidity, stabilize the pressure, to ensure that the product molding effect.

Material Science

Granulation belt made of WC-Co are connected to the die plate by vacuum brazing: they are highly wear-resistant and suitable for long-term use.

Case: WC-CoNiCr metal-ceramic composite is used for the granulation belt, and Inconel 625 is used for the template, which is connected by vacuum brazing. Compared with the traditional 316L stainless steel, the wear resistance is increased by 2~3 times, and the hardness is up to HRC75. In the environment of high temperature and high pressure, the profile variable is tiny, which ensures the stability of long-time pelletizing. For PP/PLA mixture, the life of pelletizing die plate is increased from 30 days to 4~6 months. Efficient output, directly reduce the equipment maintenance costs.

Quality Outputs

From design, processing to testing, each step is under the management of ISO9001 system documents, and the whole process can be traced and managed. To output PP pellets with better quality: smooth surface, no trailing burrs and snake skin phenomenon, ensuring high quality.

Choosing DOMIC pelletizing die plate is choosing efficiency and reliability. We help to improve efficiency!